Introduction

Introduction

Luminescence Technology Corp. (Lumtec) is an acknowledged world manufacturer in organic chemicals, eg. OLED materials. Over 20 years of abundant experiences developing innovative organic optoelectronic materials in the markets of OLED, OPV, OTFT have led Luminescence Technology to become renowned company in the chemical synthesis industry in North America, Europe, Asia and Taiwan. The company is now present in 7 locations worldwide to support its customers' demanding applications.

Lumtec product-range includes OLED material, OPV material, OTFT material, Organic Intermediates, Boronic Acid, ITO Patterned Glass and components, developed and manufactured in Hsin-Chu, Taiwan. These innovative materials reputed for their unique expertise carry the Lumtec brand-name as a guarantee of high performances and cost-effectiveness. Most of our products are kept in stock of semi-bulk quantities to offer customers the service of just-in-time delivery.

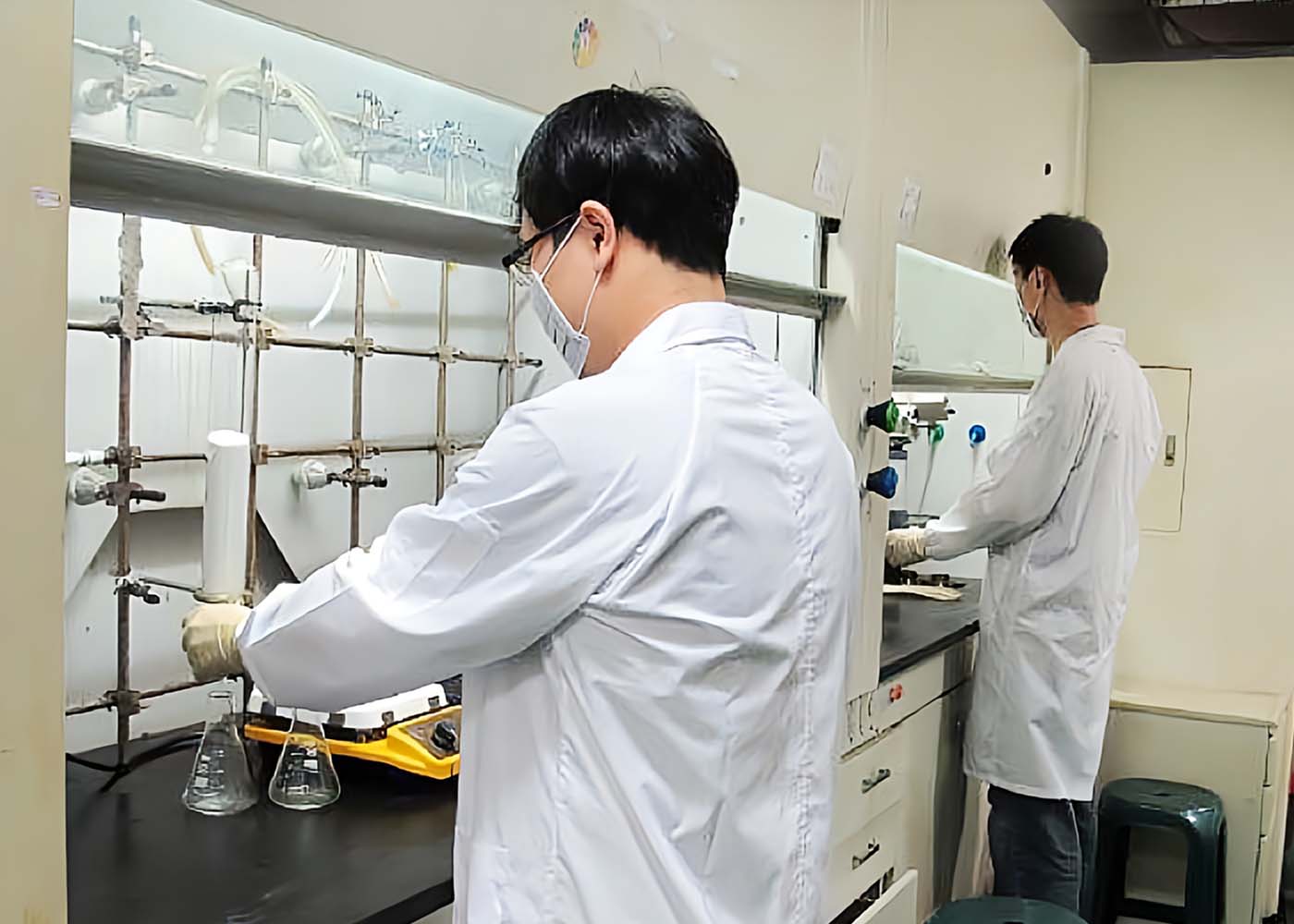

Continuously, Luminescence Technology Corp. keeps developing more advanced and innovative organic optoelectronic materials to support customers always the up-to-date products. We specifically offer custom synthesis and OEM/ODM products. Lumtec R&D team are professional experts to make related materials on demand of intermediates, reference compounds, starting materials, as well as derivatives of lead compounds, which are designed for ordering in scale range from grams to kilo-grams.

Luminescence Technology Corp. has put in place the manufacturing and service facilities required to offer high quality levels to customers. All products are inspected by modern analytical methods to meet the highest quality standards. With approach to the certifications of ISO 9001 and ISO 14001, Lumtec is aiming at the highest quality and environmental standards in service and support.

New Materials Development

Lumtec has the specialized R&D team for new materials development and production. We are fully devoted to the manufacturing of the organic optoelectronic materials, advancement of various compounds, fine purification and qualified analysis techniques. Lumtec is proud of our progressive technologies to provide extensive products for customers, and we continuously keep developing new patent materials for the future innovative applications.

Reaction Equipment

Lumtec is able to scale-up the large amounts of chemicals listed in our catalog and products of custom synthesis. Any inquiries of mass production will be very welcome.

- 50L to 500L / Glass-Lined, Stainless Steel

- Capacity : 1 ton/month

Sublimation Equipment

Lumtec specializes in repurifing materials adopting proficient sublimation skills and technigues to reach the highest level of quality. We set up the in-house sublimation equipments which are applicable for particular products and bulk quantities. We are pleased to provide all materials that are ready for use in vacuum deposition process.

- 2 inches to 10 inches quartz tubes

- Capacity : 300 kg/month

Lithographically Patterned ITO Equipment

Lumtec can supply the ITO glass cutting, cleaning and patterning service to customer requirements. The specialized pattern masking process is used, and that allows us to offer quantities ranging from small scale prototyping of research requirements to full scale production volumes.

- Maximum patterning area 150 x 150 mm

- Minimum feature dimension 0.02 mm

- Minimum spacing 0.15 mm

- Positioning accuracy 0.1 mm

- Clean room : Class 100

- Resolution : L/S < 10 μm

Vacuum Deposition Equipment

Organic material has been widely used in the application of OLED, OPV, OTFT and OPD, etc. Lumtec has set up a vacuum deposition equipment connected with a glove box, so that we can deposit required organic layers and encapsulated the device in an inert environment. Accordingly, we proceed the device test for a new designed material from the real device performance. Meanwhile, we also provide the device services for customers, which intend to optimize materials and device parameters.

It should be very helpful to confirm an optimal device before customers invest their own costly facility.

- Device fabrication: 50 mm × 50 mm x 4 pcs or 100 mm × 100 mm x 2 pcs

- Deposition sources: Organic layer x 10, metal / inorganic layer x 3, simultaneously optimizing 4 individual parameters

- Clean room : Class 1000

- Encapsulation: Cover glass, UV glue and desiccant.

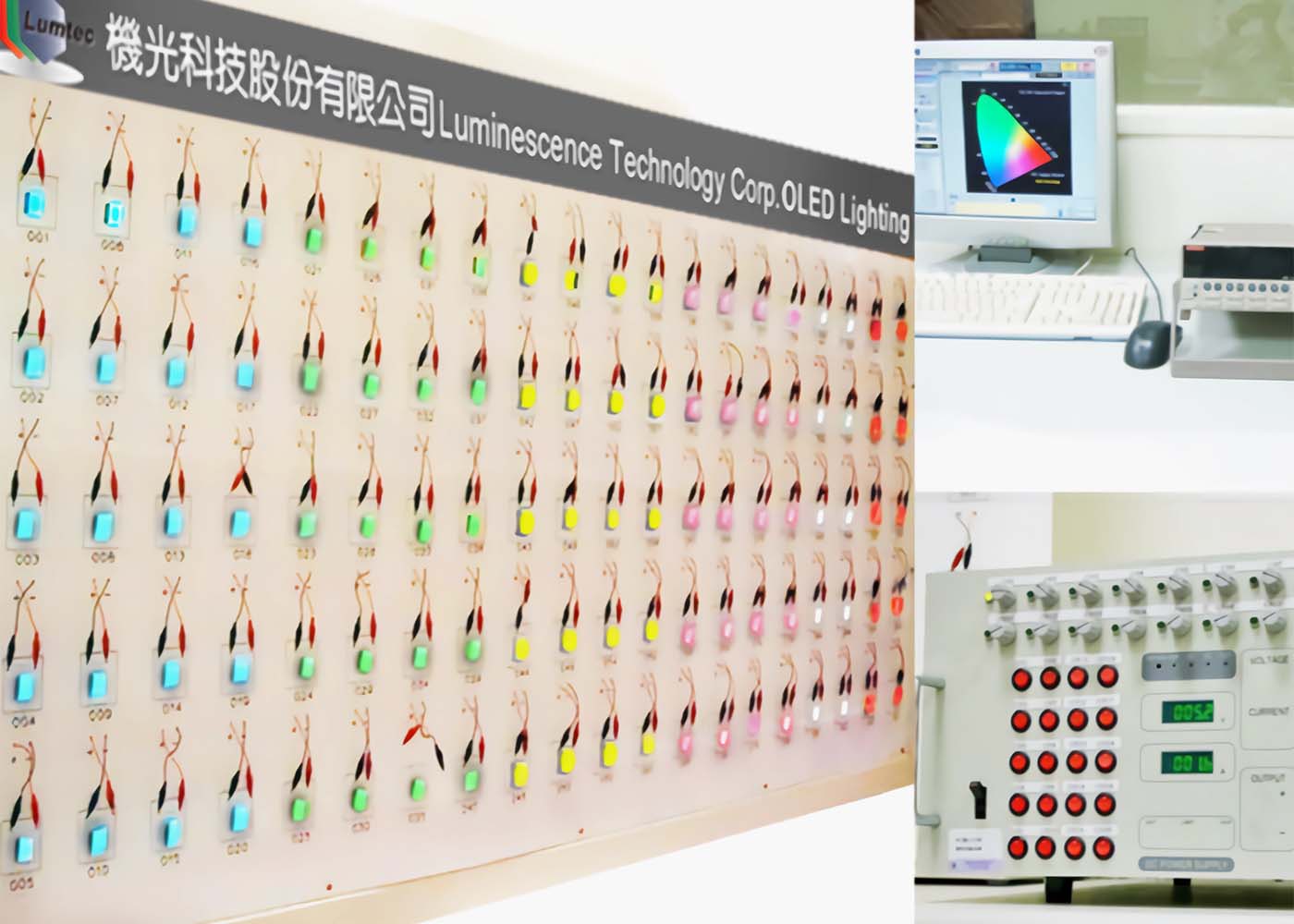

OLED Device Evaluation Equipment

Key parameter of OLED device could be determined precisely by our own dynamic device evaluation equipment, such as applied voltage, luminescence, current density, power efficiency and CIE value. In particular, we had designed an exclusive installation to record variations in lifetime.

PR-650 & Keithley 2400 SourceMeter Life-time test equipment

Quality Assurance & Control

Lumtec is committed to be the preferred global manufacturer for organic optoelectronic materials and fine chemicals. Three most essential properties of our products are quality, efficiency and diversity. To meet customer requirements and satisfaction, the certified report generated by PL, UV, HPLC, GPC and TGA as well as structure identified instrument will be applicable for Lumtec materials in order to always supply high quality products to our customers. With close connection between each department from raw materials to final production, we continuously strive improving and developing reliable techniques to fulfill customer satisfaction in the years ahead.

Custom Synthesis and OEM/ODM Materials

Any inquiry of customs synthesis for a sample trial order or mass production will be taken into a complete and thorough review and evaluation. Our commitment of competitive cost, efficient lead time, professional design and highest quality will always meet customers' satisfaction and standards.